- ZAR Lynx

- Overview

At ZAR Lynx, we are committed to delivering comprehensive, high-performance solutions by integrating global technologies with local expertise. Our success in serving the oil & gas, marine, water and industrial sectors is powered not only by our skilled team but also by our collaboration with some of the world’s most trusted technology providers. These strategic partnerships empower us to deliver innovative, efficient and safe services that meet the highest industry standards.

These collaborations allow ZAR Lynx to offer a fully integrated service approach—from industrial cleaning and maintenance to water purification and safety enhancements. Each solution is tested, proven, and aligned with international standards, making our services more effective, safe and sustainable.

By working closely with these strategic partners, we ensure our clients benefit from the latest advancements in technology, reduced operational risks, and increased cost-efficiency. Our ability to deploy high-end systems, backed by proper training, expert consultation, and after-sales support, allows us to respond quickly to project needs and deliver reliable results on time.

These partnerships are not just about distribution—they are built on shared goals, technical alignment, and long-term value creation. With these trusted names by our side, ZAR Lynx continues to raise the bar in industrial engineering solutions across Malaysia and the region.

- Products

Air Automation Group SUPAVAC

SUPAVAC provides air-powered vacuum pumps designed for safe and efficient sludge, slurry, and solids transfer. With no moving parts in contact with materials, these systems are ideal for confined spaces and hazardous environments, offering high suction and discharge over long distances.

Advanced Watertek / Gradiant

Watertek delivers custom-engineered water treatment systems, including reverse osmosis, ultrafiltration, and disinfection units. Designed for harsh environments, their systems ensure reliable, high-quality water for industrial, marine, and offshore operations with compact, skid-mounted designs.

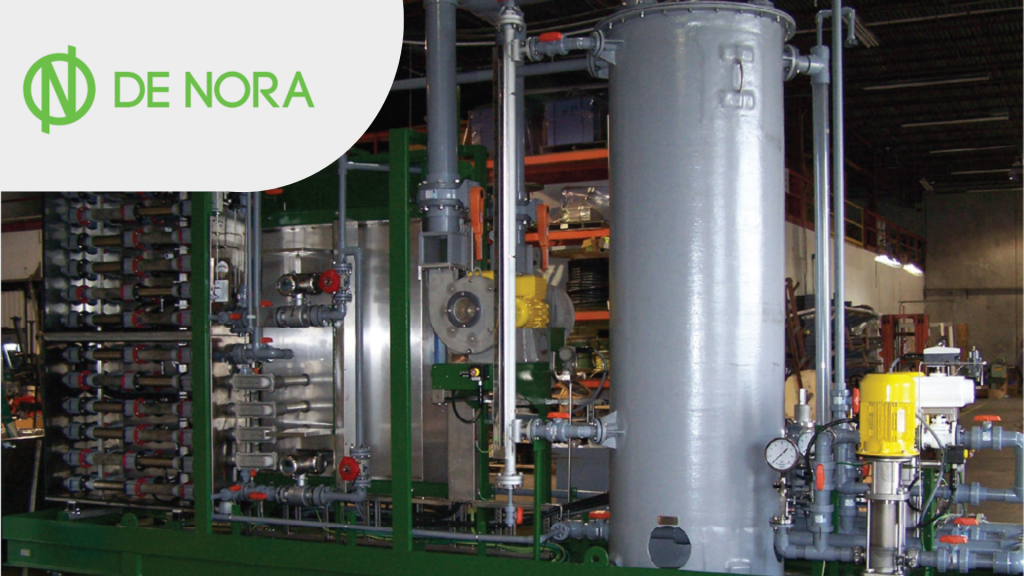

DeNora – SANILEC® & OMNIPURE™

DeNora is a leader in seawater electrochlorination and marine sewage treatment. SANILEC® systems generate safe biocides from seawater, while OMNIPURE™ treats wastewater to IMO standards. Both offer chemical-free, low-maintenance, and compact solutions for offshore and marine applications.

AQUAJET

AQUAJET system uses combination of compressed air, water and abrasive for surface preparation and coating removal. Operating only @ 100 PSI compressed air pressure to remove scale, rust and unwanted contaminants—ideal for offshore platforms, ship decks, tanks and pipelines where surface integrity is vital. The AQUAJET system eliminates the airborne dust. Thus, make it suitable for usage at enclosed area such as machinery rooms.

TRAX Anti-Slip

TRAX anti-slip covers enhance safety in industrial and marine environments. Made with fused alumina grit and fiberglass, they provide high traction on stairs, ladders, and walkways. Available in various grit grades and glow-in-the-dark options, TRAX ensures long-lasting slip resistance.

- Project Highlights

Tank / Vessel Cleaning

Desanding / Cleaning of Topside Vessels Onboard an FPSO

Scope: Cleaning of various process vessels including IP Separator, Electrostatic Treater, Crude Degasser, LP Separator, and Produced Water Degasser.

System Used: 2 units of SV60V.

Manpower: 11 personnel.

Duration: 13 days – 4 days of preparation, 7 days of desanding/cleaning, and 2 days of housekeeping.

Result: Full cleaning of topside process vessels with reduced downtime and enhanced safety.

RO Watermaker Maintenance

Commissioning of RO System Onboard an FSO

Scope: Commissioning of RO water maker system onboard an FSO.

System Used: RO Water Maker unit with 2 × 20 m³/day production capacity.

Manpower: 2 pax

Duration: 7 days

Result: RO system was successfully commissioned and made operational, enabling onboard production of potable water. This ensured reliable freshwater supply for the facility.

Hypochlorite Generator Maintenance

Sodium Hypochlorite Maintenance Onboard an Offshore Platform

Scope: Scheduled maintenance and system optimization for an existing hypochlorite generator system.

System Used: Sodium hypochlorite generation system.

Manpower: 2 pax

Duration: 5 days maintenance session including cleaning and troubleshooting.

Result: Carried out chemical cleaning of 4 electrolytic cells, degassing tank, piping and valves. Completed troubleshooting and conducted hands-on system training for platform operators. System restored to peak operational performance.

AQUAJET Wet Abrasive Blasting

Wet Abrasive Blasting of a Heavylift Pipelaying Barge

Scope: Wet abrasive blasting and painting works for crane mast and boom, covering a total surface area of 1500 m².

System Used: 3 units of AQUAJET wet abrasive blasting system.

Manpower: 8 pax per 12 hours shift

Duration: 2 weeks

Result: Completed multi-coat repainting after surface treatment, ensuring corrosion protection and extending crane service life.