- Project Highlights - Tank Cleaning / Pumping

Mud Cleaning – LNGC Puteri Zamrud

Scope: Mud cleaning of Tank No.1 STBD involving 40 tonnes of sludge.

System Used: 1 unit of SV110V.

Manpower: 9 personnel.

Duration: 6 days total – 2 days preparation and 4 days of pumping and washing from 08:00 to 23:00 daily.

Result: Successful removal of 40 tonnes of mud using SupaVac, improving efficiency and safety compared to manual methods.

Mud Cleaning – MT Nautica Renggam

Scope: Cleaning of water ballast tank (WBT) containing approximately 200 tonnes of mud.

System Used: 1 unit of SV110V and 1 unit of SV60V.

Manpower: 7 personnel.

Duration: 6 days total – 2 days preparation and 4 days of pumping from 08:00 to 23:00.

Result: Efficient removal of heavy mud content, significantly reducing labor and time.

Mud Cleaning – LNGC Shien Hai

Scope: Mud cleaning of Ballast Tank 3 STBD, 4 STBD and 4 PORT. Total sludge volume of 1300 tonnes.

System Used: 3 units of SV110V and 1 unit of Wilden pump.

Manpower: 30 personnel.

Duration: 10 days total – 1 day preparation and 9 days of continuous 24 hours operation of 2 shifts.

Result: Thorough cleaning demonstrating the power of SupaVac technology combined with annual cleaning.

Sludge Cleaning – MV CTP Honour

Scope: Sludge and mud cleaning of 19 tanks including Fore Peak, AFT Peak, and multiple fuel oil tanks.

System Used: 1 unit of SV110V, 2 units of Graco Husky 2150, and 1 unit of Graco Husky 550.

Manpower: 10 personnel.

Duration: 9 days – 2 days preparation and 7 days of active cleaning.

Result: Effective cleaning of a multiple types of tanks following marine sludge handling requirements.

Sludge Removal – FSO ABU

Scope: Sludge removal from Slop Tank 6C at a production rate of 6 tonnes per hour.

System Used: 1 unit of SV110V.

Manpower: 8 personnel.

Duration: 6 days – 2 days preparation and 4 days of operation from 08:00 to 23:00.

Result: High-efficiency sludge pumping achieved, with minimal manual involvement.

Desanding / Cleaning of Topside Vessels Onboard an FPSO

Scope: Cleaning of various process vessels including IP Separator, Electrostatic Treater, Crude Degasser, LP Separator, and Produced Water Degasser.

System Used: 2 units of SV60V.

Manpower: 11 personnel.

Duration: 13 days – 4 days of preparation, 7 days of desanding / cleaning, and 2 days of housekeeping.

Result: Full cleaning of topside process vessels with reduced downtime and enhanced safety.

Pumping & Cleaning – Techno Indah

Scope: Pumping and cleaning of two slop oil tanks containing a total of 1600 tonnes of sludge.

System Used: 2 units of SV110V.

Manpower: 12 personnel.

Duration: 10 weeks – 6 weeks for sludge pumping, 3 weeks for cleaning, and 1 day for housekeeping.

Result: Complete sludge management and tank cleaning for plant decommissioning.

Tank Cleaning – ATT Tanjung Bin

Scope: Cleaning of 11 storage tanks ranging from 23 meters to 56 meters in diameter.

System Used: SupaVac pump combined with manual cleaning.

Manpower: 15 – 30 pax

Duration: 6 – 15 days

Result: Successful tank cleaning operations across a multiple types of petroleum products storage facility, reinforcing SupaVac’s suitability for large-scale projects.

Download Our PDF

- Project Highlights - Wet Abrasive Blasting

Water Jetting – S3000 Crane Boom

Scope: High-pressure water jetting and painting works for crane mast and boom, covering a total surface area of 1500 m².

System Used: 1 unit of high-pressure water jet system.

Manpower: 8 personnel.

Duration: 2 weeks.

Result: Completed multi-coat repainting after surface treatment, ensuring corrosion protection and extending crane service life.

Wet Abrasive Blast – S3000 Main Deck

Scope: Blasting and painting of the main deck (2000 m²), 40-tonne port & starboard cranes, and boom area of a 3000-tonne crane.

System Used: Wet abrasive blasting equipment.

Manpower: 8 personnel (working in 2 shifts).

Duration: 18 days.

Result: Achieved SA 2.5 surface prep quality and applied protective coatings, restoring large marine deck surfaces to operational readiness.

Wet Abrasive Blast – S3000 Main Deck

Scope: Hydrojetting at 3000 PSI and 3-coat painting of lay stringer components.

System Used: Hydrojetting system.

Manpower: 12 personnel.

Duration: 2 weeks.

Result: Surface fully prepped and protected with multi-layer coating, ensuring resilience against marine conditions.

Wet Abrasive Blast – FSO Nautika Mekar

Scope: 800 m² chemical washing, abrasive blasting (SA 2.0), vacuum cleaning, 10,000 PSI high-pressure washing, and 3-coat epoxy painting.

System Used: Wet abrasive blasting, vacuum and high-pressure wash system.

Manpower: 8 personnel.

Duration: Not explicitly stated (completed in sequential process phases).

Result: Delivered full surface refurbishment with high-performance epoxy coating, meeting offshore standards.

Wet Abrasive Blast – FPSO Kikeh (Inert Gas Cooling Tower & Deck Seal)

Scope: Wet Abrasive Blasting and application of 3-layer high temperature NOVOLAC paint of inert gas cooling tower and deck seal internal structure.

System Used: AQUA-JET Wet Abrasive Blasting

Manpower: 6 pax

Duration: 14 days

Result: Corrosion prevention and integrity restoration.

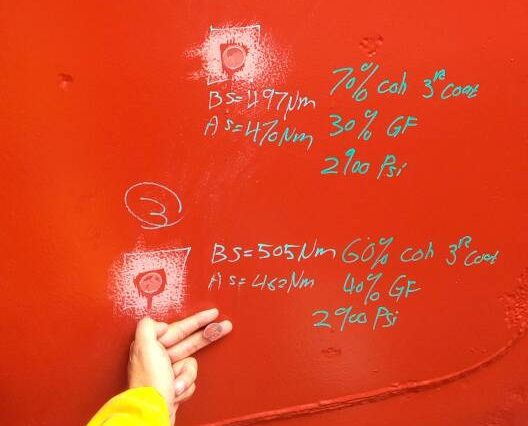

Wet Abrasive Blast – Jack Up Rig EP7

Scope: Surface treatment over 2800 m² using 4 blasting nozzles to achieve SA 2.5 finish.

System Used: AQUA-JET Wet Abrasive blasting equipment.

Manpower: 24 personnel.

Duration: 30 days.

Result: Pull-off test reached 2900 PSI, confirming excellent surface bonding and preparation standards.

Wet Abrasive Blast – FPSO Kikeh (ARCOR Coating)

Scope: Surface wet abrasive blasting of 12 m² using 1 blasting nozzle, to SA 2.5 standard, coated with ARCOR EE950HT.

System Used: AQUA-JET Wet Abrasive blasting and ARCOR high-temperature resistant epoxy.

Manpower: 5 pax

Duration: 10 days

Result: Surface coated with ARCOR for durability in high-temperature environments, extending lifespan of the component.

Download Our PDF

- Tank Cleaning - Engine Room Bilge Well

Date: November 2019 | Location: Offshore Floating Facility | Duration: 2 weeks | Manpower: 8 pax |

The cleaning was performed utilizing the Supavac SV60V solid/slurry pumping system to vacuum and remove sludge/debris from the very tight space

- Water Treatment Technologies - Sodium Hypochlorite Generator Maintenance

Date: September 2017 | Location: Sabah | Duration: 5 days | Manpower: 3 pax |

Capacity: 8kg/hr | Maker: AMPAC-PEPCON | Scope of Work: Scheduled Maintenance Chemical Cleaning

- Tank Cleaning - Oil/Sludge Processing Facility

Date: November 2018 | Location: Johor | Duration: 2 weeks | Manpower: 10 pax | Average Daily Production: 60 ton to 80 ton per 8 hour |

The cleaning was performed utilizing the Supavac SV110V solid/slurry pumping system to vacuum and remove sludge/debris

- Water Treatment Technologies - Sewage Treatment System Maintenance

Date: February 2020 | Location: Malacca Strait | Duration: 5 Days | Manpower: 5 pax |

Scope of work: 1. Pumping of sludge into IBC tank for disposal onshore 2. Cleaning of internal/external compartment/equipment and painting of damaged coating areas. 3. Testing of alarm and trips. 4. Chemical flushing of vent pipes 5. Calibration of chlorine and de-chlorination dosing. 6. Sampling collection and laboratory analysis on monthly basis.

- Water Treatment Technologies - Oil Water Separator Maintenance

Date: February 2020 | Location: Malacca Strait | Duration: 5 Days | Manpower: 5 pax |

Scope of work: 1. Pump remaining oil/sludge to IBC tank located on main deck for disposal onshore. 2. Removal of internal components for cleaning/renewal. 3. De-greasing and cleaning of internal compartment and top covers. 4. Power brush, sanding and painting 3 coats. 5. Reinstall internal components and top cover.

- Wet Abrasive Blasting - Auxiliary Condenser End Covers Recoating

Date: March 2019 | Location: Offshore Floating Facility | Duration: 2 weeks | Manpower: 6 pax|

| Product: ARCOR EE12HT | DFT: >1000 Micron | Surface Prep: Mechanical Scraping, Power Brush, Wet Abrasive Blasting & Dry Sweep Blasting to achive S.A 2.5|

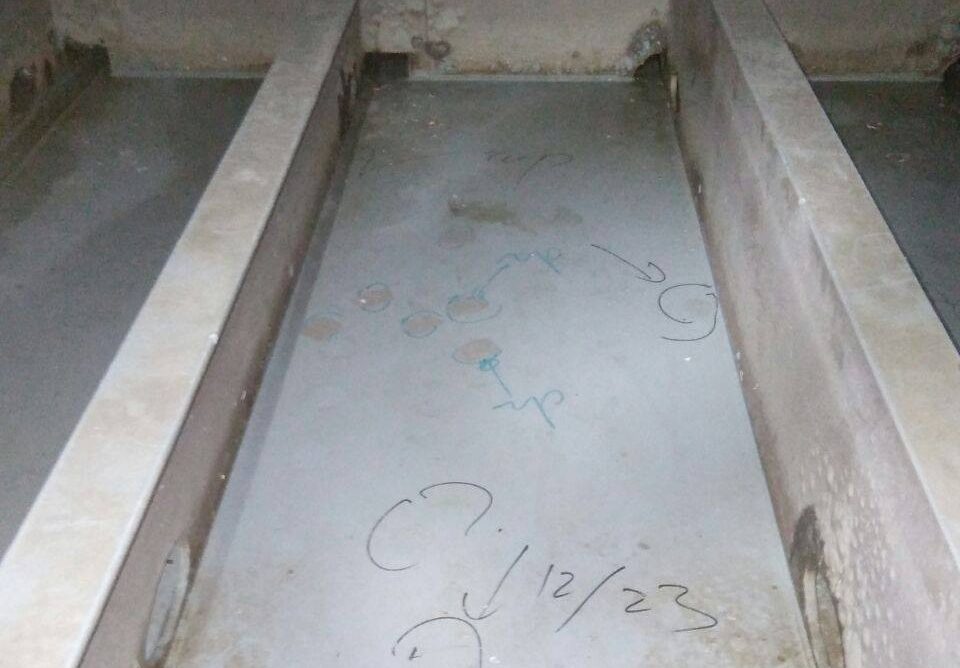

- Tank Cleaning - Jack Up Rig Mud Pumping

Date: April 2019 | Location: Pasir Gudang | Duration: 5 Days | Manpower: 12 pax |

Scope of work: Spudcan mud pumping x 3 units Estimate mud quantity = 150 tons Equipment = 1 x Supavac SX60V & 1 x Supavac SX110V (8 meters negative suction head)

- Tank Cleaning - MGO/HFO Tank

Date: April 2018 | Location: Offshore Floating Facility | Duration: 5 Days | Manpower: 7 pax |

Equipment: 1. Guzzla SX110V x 1 unit 2. Wilden Pump x 1 unit 3. Air Compressor x 1 unit 4. Chemical x 1 lot 5. Tank cleaning accessories and consumables x 1 lot

- Wet Abrasive Blasting

Date: August 2018 | Location: Pasir Gudang | Duration: 30 Days | Manpower: 24 pax |

| Scope of work: BLASTING & PAINTING EXTERNAL HULL | AREA: 2800 M2 | NUMBER OF BLASTING NOZZLE = 4 PCS | SURFACE PREPARATION QUALITY:S.A 2.5 PULL OFF TEST: 2900PSI

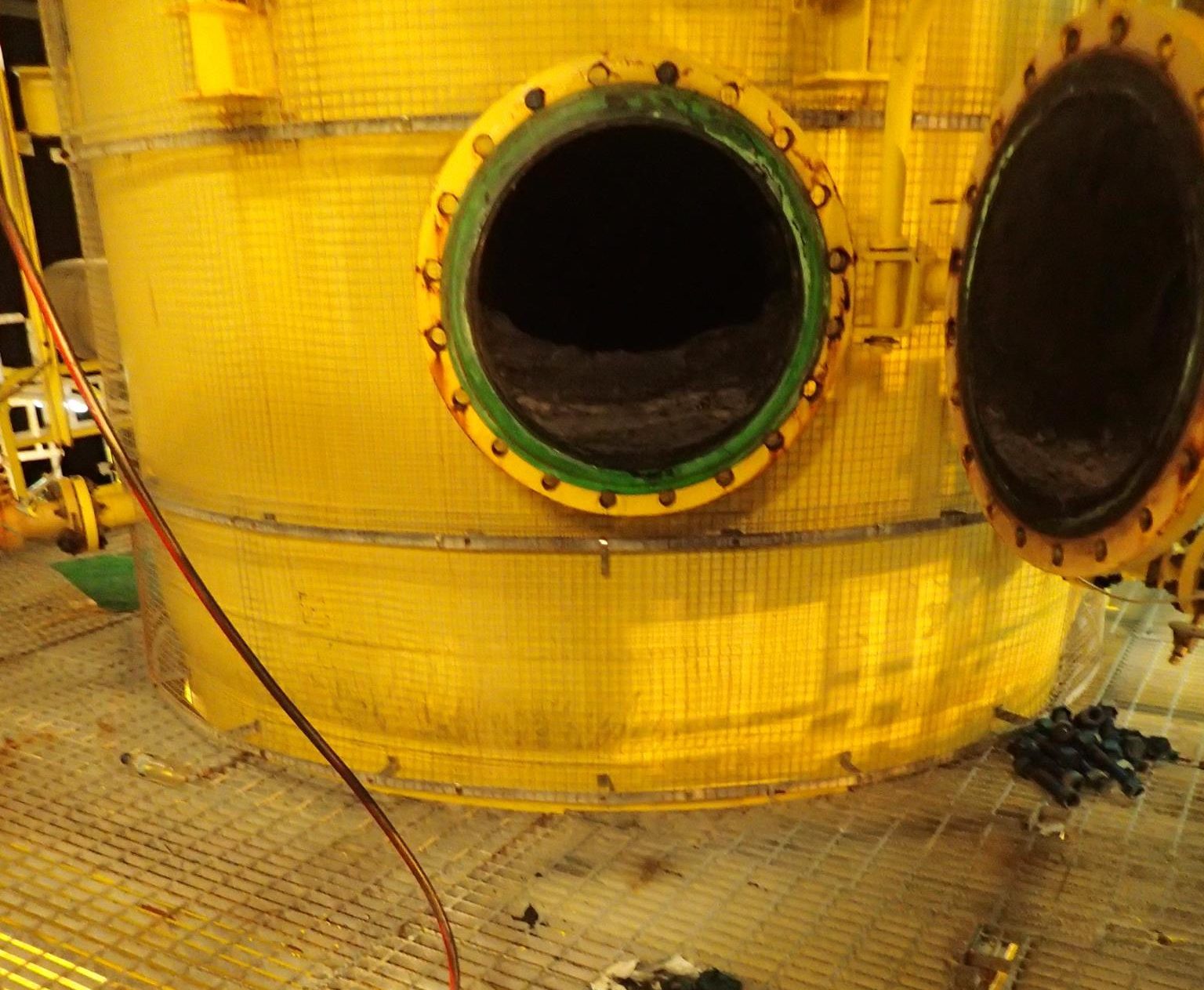

- Vessel Cleaning

Date: October 2016 | Location: Sabah | Duration: 12 days | Manpower: 11 pax (24h operation) |

| Number of vessel : 5 | Equipment: 2 Unit SX60V Sludge and Slurry Pump c/w hose & accessories | Volume of sand/sludge removed: 180m3

- LNG Carrier DO/HFO Tank Cleaning

Date: July 2017 | Location: Pasir Gudang | Duration: 6 days | Manpower: 5 pax |

| Equipment: 1 Unit SX110V, 1 Unit Wilden pump, 1 Lot Tank Cleaning Accessories | Tank pumping: 30 Tons HFO & 110 Tons Sludge

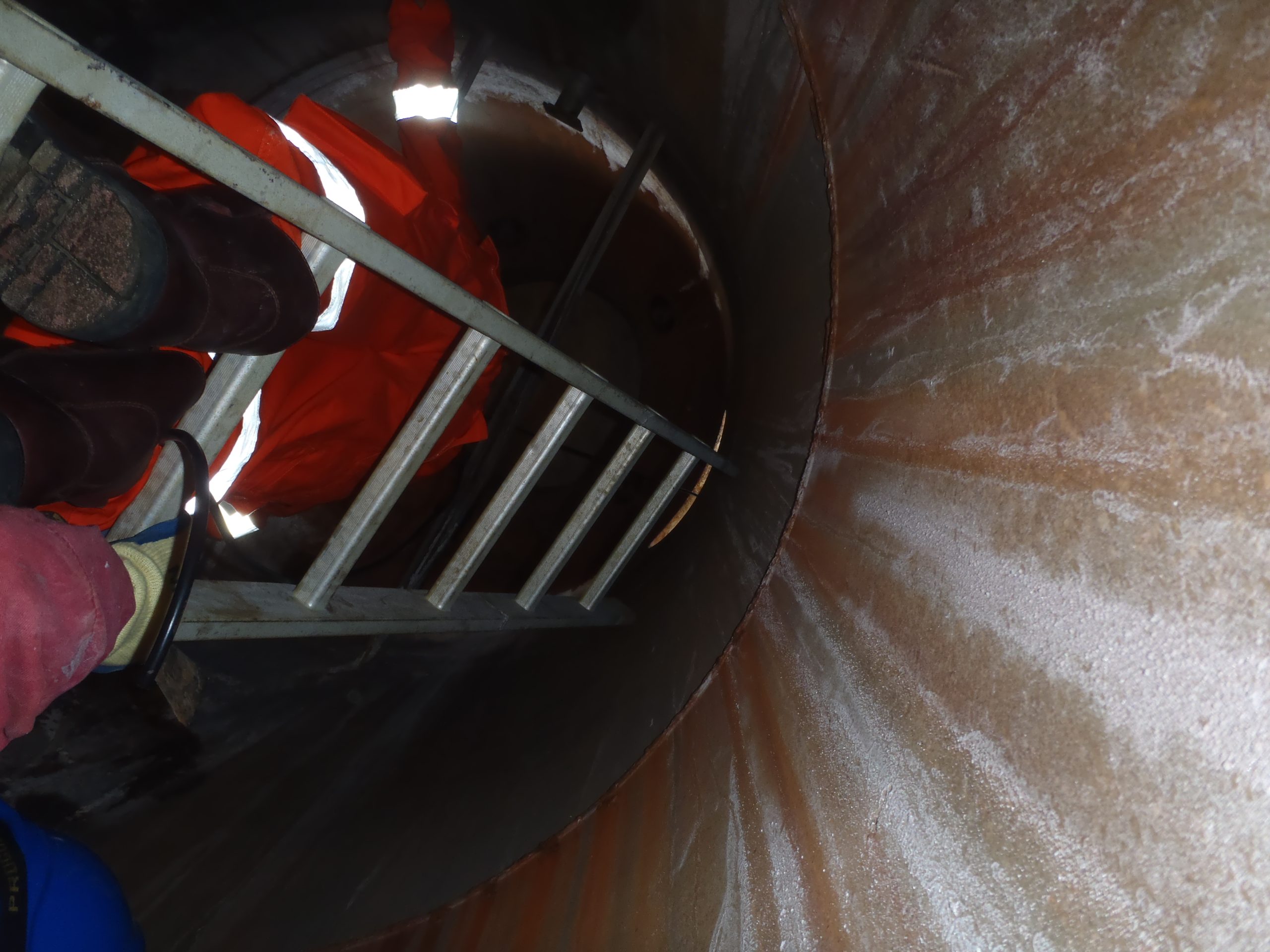

- LNG Carrier Ballast Tank Mud Removal & Cleaning

Date: July 2017 | Location: Pasir Gudang | Duration: 6 days | Manpower: 30 pax |

| Equipment: 3 Unit SX110V, 1 Unit Wilden pump, 1 Lot Tank Cleaning Accessories | Total Weight of Mud: 1300 tonnes